What Is a Scrap Metal Baler?

Understanding the Basics

A scrap metal baler is a powerful recycling machine designed to compress various types of scrap metals—like aluminum, copper, and steel—into compact, manageable bales. These bales are easier to store, transport, and sell to recycling facilities.

Why Are Balers Essential in Scrap Recycling?

Balers are essential for turning chaotic piles of scrap into neatly packed, space-saving cubes. This not only improves storage efficiency but also boosts the value of the recycled material. Scrap yards, recycling centers, and even large manufacturers use these machines to streamline their metal waste management.

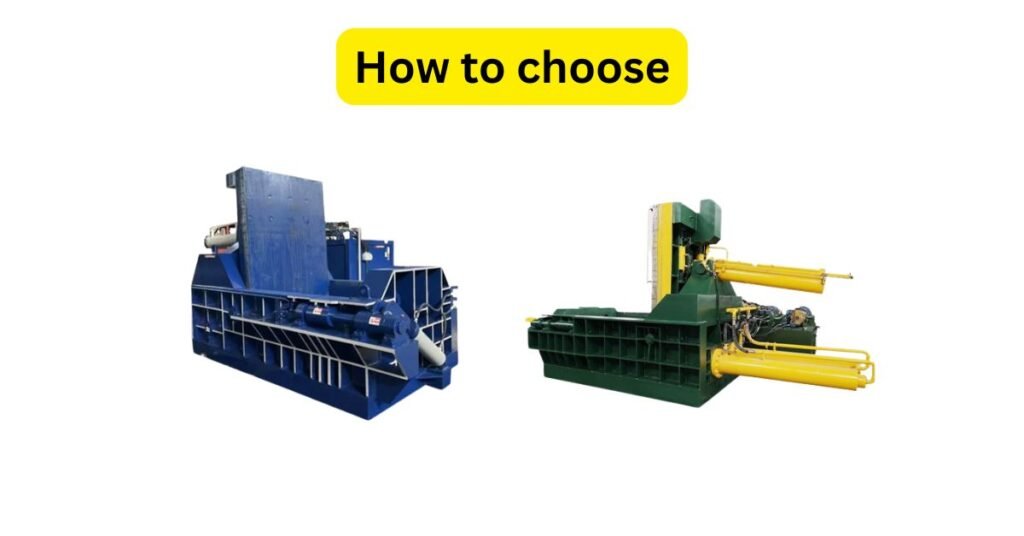

Types of Scrap Metal Balers

Horizontal Balers

Perfect for high-volume operations, horizontal balers work continuously and can handle large amounts of scrap. They typically offer automation and conveyor feeding options, making them ideal for industrial setups.

Vertical Balers

These are compact, upright machines that compress metal from the top down. They’re suited for smaller facilities with limited space but lower scrap volume.

Mobile and Portable Balers

Need to work at multiple locations? Portable balers can be transported to different job sites, allowing for on-site baling, especially useful for demolition companies or traveling recycling units.

Two Ram vs Single Ram Balers

Single ram balers use one compression chamber and are simpler, while two ram balers provide higher force and allow for denser bales and faster cycles, perfect for mixed or heavy-duty scrap.

Key Features to Consider

Baling Force and Pressure

Measured in tons, this is a critical factor. Higher baling force means tighter bales, which are easier to transport and fetch better market prices.

Bale Size and Density

Make sure the baler can produce the size and density required by your buyers or transportation limitations. Denser bales save shipping costs.

Loading and Feeding Method

Some machines use hoppers, others manual loading. Conveyor systems are ideal for large-volume operations to automate feeding.

Automation and Control Systems

Modern machines come with touch-screen controls, PLC systems, and auto-shutoff features. These make operations smoother and safer.

Build Quality and Material Strength

Look for machines built with high-grade steel. They last longer and withstand harsh working environments better.

Choosing the Right Metal Scrap Baler for Your Needs

Volume and Type of Scrap Processed

Are you processing light aluminum cans or thick steel bars? Your answer will directly influence the size, power, and design of the baler you need.

Space Constraints

Got limited floor space? Go for vertical or compact horizontal balers. Make sure to check the footprint and loading area.

Operational Efficiency and Throughput

Measure how fast the baler works. You’ll want something that can match your scrap output without constant downtime.

Maintenance and Durability

Machines that require less frequent maintenance and offer easy access to parts will save time and money long-term.

Scrap Metal Baler Machine Safety

Built-in Safety Features

Look for emergency stops, safety guards, auto-shutoff sensors, and overload protection. Safety is a non-negotiable.

Operator Training and SOPs

Your team must know how to run the machine efficiently and safely. Invest in training and enforce proper operating procedures.

Budget Considerations and ROI

Upfront Costs vs Long-Term Savings

A cheaper baler might seem appealing but may cost more in downtime, repairs, or inefficiency. Calculate the long-term return on investment.

Used vs New Balers

Used machines can be a great deal if well-maintained. Always inspect thoroughly, or better yet, buy from a trusted refurbisher.

Environmental and Regulatory Compliance

Meeting Local Recycling Standards

Ensure the baler is compliant with environmental and waste management regulations in your region to avoid fines or legal trouble.

Energy Efficiency

Energy-efficient balers reduce your carbon footprint and operating costs. Some models come with eco-modes or optimized motors.

Where to Buy a Scrap Metal Baler?

Trusted Manufacturers

Brands like Sierra, Harris, and Enerpat are industry leaders. They offer warranties, customer support, and durable machines.

Things to Watch for When Buying Used Equipment

Check the machine’s history, hours of use, service records, and inspect hydraulics, wiring, and control panels.

Scrap Rates Today

Final Checklist Before Buying

- What’s your scrap volume and type?

- How much space do you have?

- Do you need mobility?

- Is automation essential?

- What’s your budget and ROI expectation?

- Is the supplier reputable?

Tick off these boxes before you make that big purchase.

Conclusion

Choosing the right scrap metal baler isn’t just about finding a machine that compresses metal—it’s about finding one that fits your operation like a glove. Think about your volume, space, safety, and budget. Consider both your current needs and future growth. Whether you’re just starting out or upgrading your recycling line, the right baler can boost your efficiency, profits, and sustainability.

FAQs

1. What metals can be processed in a scrap metal baler?

Most balers can handle aluminum, steel, copper, iron, brass, and even car body parts depending on their capacity and build.

2. How long does a baler machine last?

With proper maintenance, a good-quality baler can last 10–20 years or more.

3. Can a metal scrap baler be customized?

Yes, many manufacturers offer customizable features including feeding methods, bale sizes, and control systems.

4. Are portable scrap metal balers worth it?

Absolutely, if you operate at different sites. They provide flexibility and save on logistics.

5. How do I maintain a scrap metal baler?

Follow the manufacturer’s maintenance schedule. Regularly check hydraulic systems, lubrication points, and safety features.